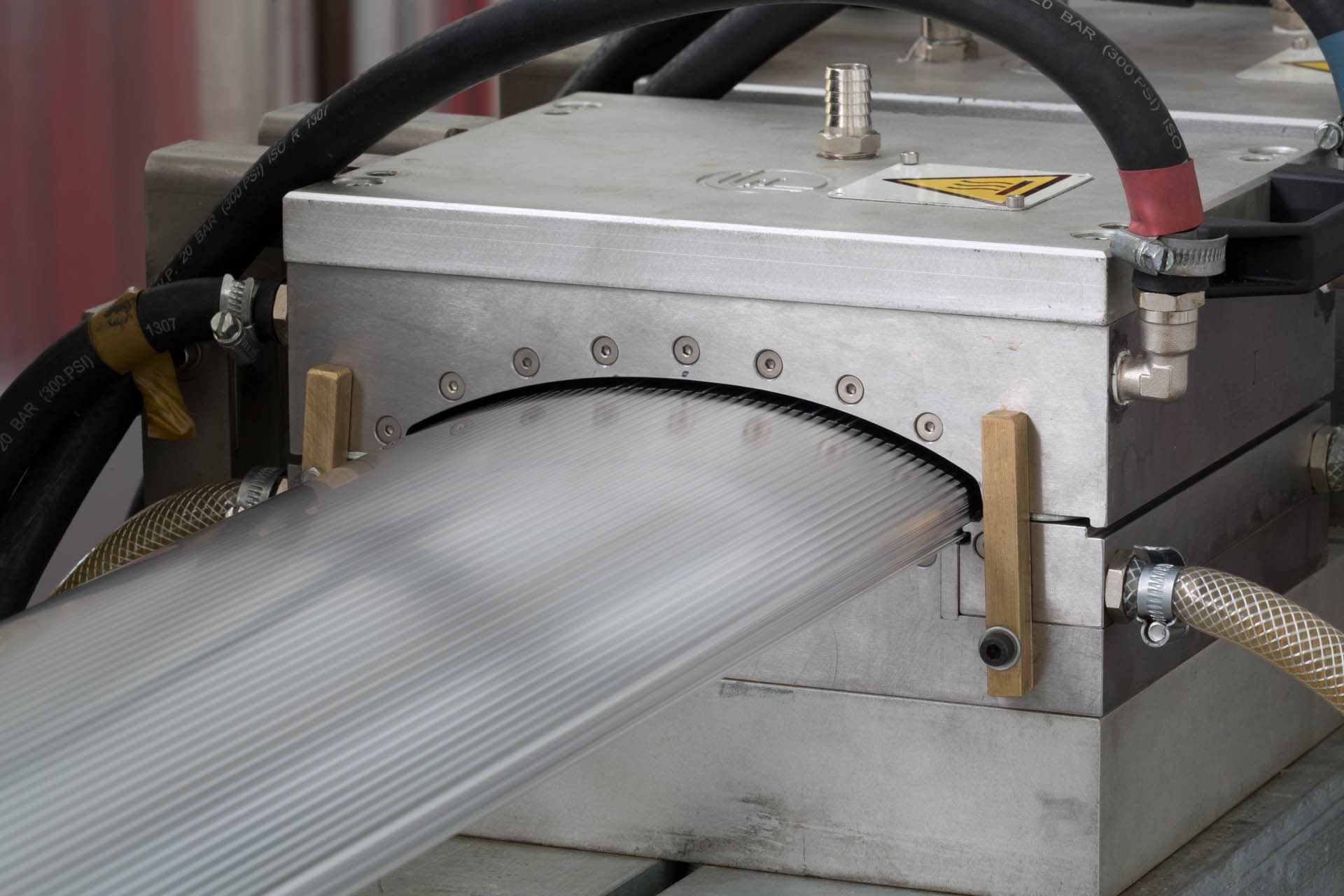

Production facility in Senica is equipped with 8 latest injection moulding machines from reputable KRAUSS MAFFEI and HAITIAN. There are also dryers (COLORTRONIC), thermoregulatory devices (TOOL-TEMP and REGLOPLAS), plastic crushers (RAPID), and conveyor belts with separators (VIRGINIO NASTRI). A three-axis robotic CNC device (from Sonderhoff – EDF) is used to apply two-component polyurethane sealing material. An extruder (from Friul Filiere) is used for profile extrusion.

We have the capacity and areas for potential expansion of production.We closely co-operate with suppliers of the latest technologies and materials.We are able to comply with request of production.